DAIMLER & HANOVER: The World’s Biggest Truck Manufacturer at the World’s Biggest Truck Show

If there’s one thing that stood out at IAA Transportation - the world’s biggest truck show - at Hanover in Germany, it was the prevalence of alternative power sources to diesel.

To put this in perspective there were 1,402 exhibitors at the show with nearly two thirds being international companies, and nearly all of them were displaying a future without ‘Black Gold’. That the world’s leaders in the transport industry are so hell bent on developing drive trains that aren’t reliant on ‘Texas T’ was an eye opener to someone from Oz, whose experience with alternative power has been limited to a run around in Daimler Truck’s electric Fuso eCanter.

As impressive as that truck is, it is only really applicable for ‘last mile’ delivery at this point in time. But if these guys have their way, the changes so derided by most Aussie truck owners are definitely coming.

The distance electric powered vehicles can travel is constantly increasing and the research and development of hydrogen power as an alternative to diesel is exploding. Daimler, the world’s largest manufacturer of heavy duty trucks is spending $billions developing these alternatives – cognisant of the fact that electric will not suit all markets. They are not alone.

M-B’s Gen H2. Hydrogen with over 4000Nm possible.

Along with Daimler; Volvo, DAF, MAN, Scania and Iveco – in fact all truck manufacturers are investing in fuel cell, electric and hydrogen technology. And a manufacturer of diesel engines (and sure to disappoint those died-on diesel lovers) has also joined the fray. Cummins – described by a Daimler executive as the ‘last man standing’ in truck engine production outside the OEM’s, proudly displayed their hydrogen alternative at Hanover. It appears that Cummins recognises that it is do-or-die. Allison Transmissions is also on board with their eGen Power family of fully electric axles.

Fully aware of the long distances travelled in countries such as Australia, Daimler is investing heavily in partnership with third parties on the development of hydrogen fuel-cell vehicles. A typical fuel cell will put out 150 kW and is compact enough for two or even 3 to be placed within a truck, giving plenty of power for the multi combination trucks in this country.

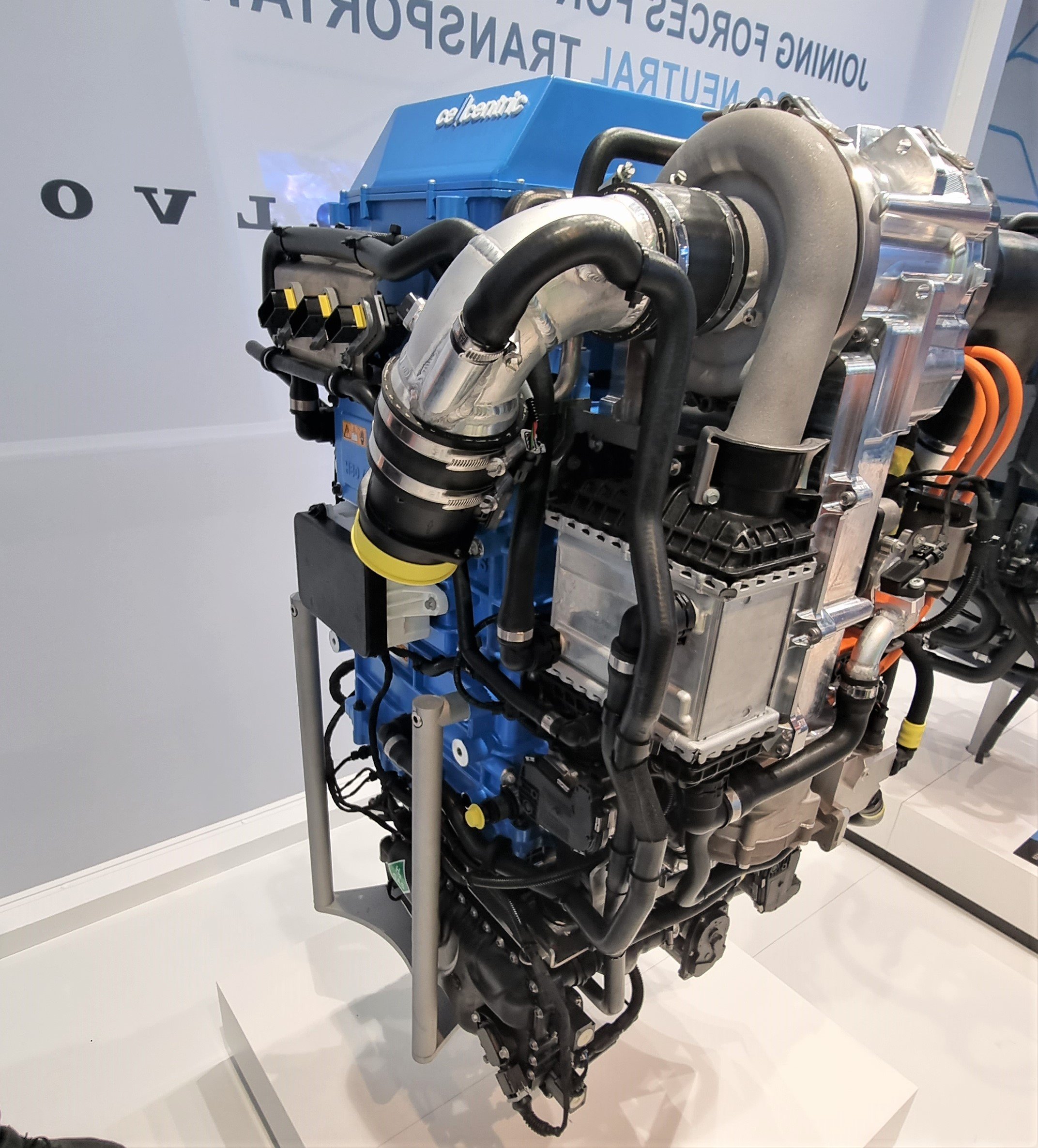

cellcentric’s fuel cell

Hydrogen appears to be the answer to long distance trucking, so essential to the Australian market. Hydrogen will give similar range and power as diesel, can be refuelled as quickly and of course leaves no pollution. Yes, its production is currently largely reliant on fossil fuels but this will rapidly change to renewables.

For those that will miss the sound of a throbbing diesel donk, I suggest putting a couple of loud speakers on the cab roof and pipe a loop recording of a 6V72 through them.

But in lieu of that sound you’ll get two fuel-cell units each putting out 150Kw (for a total of 400Hp) plus a battery to provide an additional and temporary 400Kw (536Hp) – well that’s what this GenH2 Actros puts out! Those 400 horses are going to breeze down the road and for hill climbing and that extra fast start from the lights, you’ll be able to call upon over 900 of the beasts. Mercedes-Benz talks the Torque as being up to over 4,00Nm. That’s a lot of grunt!

To develop fuel cells, Daimler has joined forces with Volvo and founded cellcentric. That will be the subject of another story.

Befitting its status as the biggest truck manufacturer, Daimler had the largest display area at Hanover, equalling in my estimation 15 odd stands at the Brisbane truck show. The pavilion they were in was as big as the entire Brisbane Truck Show footprint - and there are some 27 pavilions! There were two restaurants, bars and multiple coffee outlets servicing the Daimler stand alone. They were good too – I tried them all.

Daimler took over an entire hotel to accommodate its staff and journalists from around the world. You don’t do that unless you’ve got important news to impart – and Daimler did. At the media launch the night before the show proper, Daimler unveiled its latest electric powered eActros rigid, capable of 500km, the next generation eCanter and in pride of place, the eActros 4x2 prime mover (99% of trucks in Europe are 4x2).

Taking centre stage was the worldwide launch of the battery-electric Mercedes-Benz eActros LongHaul prime mover. In consultation with customers, the top three issues to be addressed with this truck were range anxiety, higher investment and uncertainty about reliability.

The batteries in the eActros LongHaul employ lithium-ion phosphate cell technology (LFP) which offers a longer service life than other technologies and more usable energy, equating to a longer range. Customers will be able to do ‘megawatt charging’ which will allow the batteries to be charged from 20 to 80% in well under 30 minutes at such charging stations.

A full charge will give the eActros LongHaul a range of around 500 km. While this distance is nothing in Australian terms, 60% of long haul trips in Europe are shorter than 500 km so many customers will not need to rely on public charging but rather ‘fill up’ when the truck returns to the depot. To address the need for some to recharge whilst on the road, Daimler have entered into a joint venture with Volvo and TRATON to build public infrastructure across Europe. The company believes that these steps will address any concerns regarding range anxiety.

The cost of purchasing electric is more expensive than the equivalent diesel truck but the eActros LongHaul will have a much lower energy consumption per kilometre compared to diesel – in fact less than half, meaning lower running costs. Mercedes says that over five years at 120,000 km per year the electric version will amortise costs on par with a diesel truck and from that point on the customer is ahead.

The LongHaul is currently being trialled on public roads, to be followed next year by selected customer testing with full series production to commence in 2024. From Mercedes’ first electric truck in 2016 the company is moving forward at an ever increasing rate in this field, as is every other OEM. In 2018 Daimler Truck had just one zero-emission vehicle in series production – the FUSO eCanter light truck. Today they have a portfolio of eight different zero-emission vehicles in production in Europe, Japan and the Americas.

Karin Radstrom, CEO Mercedes-Benz Trucks, articulated the company’s philosophy moving into the future. Whilst many other electric trucks are still built like their diesel equivalent, Mercedes fundamentally changed the layout of the entire electric vehicle. Two e-motors sit directly at the e-axle, effectively making the power source and differential one unit, unlike earlier iterations where the electric motor was connected via a tail shaft. This new compact design frees up space between the chassis rails for more batteries, increasing the driving range for the Actros.

eActros 300

Backing up the eActros LongHaul, the eActros 300 can tow all common European trailers just like a diesel truck. It houses three battery packs with 112 kWh each, giving a range of up to 220 km and can deliver 400 kW peak and 330 kW continuous power. The truck will go into series production in the second half of 2023.

The Mercedes-Benz eEconic was also on display. Designed for municipal services such as waste collection, the truck has three battery packs providing sufficient charge to carry most drivers through their whole shift. Two of these vehicles which were launched in July are now in Australia undergoing evaluation.

eEconic

The company is also working on the Mercedes-Benz eAtego, a medium duty electric truck coming in the next few years and completing the company’s range in the distribution segment. The eEconic and eAtego zero emission trucks are designed for urban transport covering distribution, municipal and construction duties.

Whilst the emphasis on the Daimler stand was on alternative fuel sources, the company also introduced the latest Actros L (as it is called in Europe), the company’s premium diesel powered long haul truck.

Actros L

The truck incorporates a number of changes and improvements, the most visible of which is the MirrorCam, of which I will was already a huge fan. In its latest iteration the camera arms have been shortened by 10 cm to reduce chances of damage. The ‘mirrors’ placed on the A pillars now have nearly the same perspective as normal mirrors making reversing even easier. The tone of mapping of the cameras has also been improved meaning that the displays show contrast better than before which helps a lot when driving in the dark. I noticed that DAF and Scania also dispayed their versions of MirrorCam.

The drivetrain has also received attention with the heavy duty OM 471 engine using up to 4% less fuel consumption compared to the previous generation. The 12 speed gearbox - already a winner in my book - now features gearshift’s up to 40% faster.

For those wanting the ultimate in luxury the company is producing what they call ‘Edition 3’ which has over 30 special features on both the exterior and the interior of the truck. Only 400 units will be produced, all in left-hand drive, so we will unfortunately miss out on this ‘Rolls-Royce’ Actros here in Australia.

Edition 3 dash (top) and dance floor/recreation area (below)

After the company’s presentations I was invited to get behind the wheel of the eActros rigid truck for a spin around the streets of Hanover. I’ve driven smaller electric powered trucks but this, by dint of size alone was another-world experience. Big, beautiful and above all silent, the truck wafts along the road with just the sound of the air-conditioning interrupting your thoughts. Plant your foot on the pedal and it jumps forward like a scalded cat. Admittedly there was no payload on board but I have no doubt that it would win the traffic light races against any diesel powered competition.

My driving experience with the steering wheel on the left-hand side was only tempered on one occasion when I rubbed the right-hand tires up against the curb going around long curve. My German host was urgently saying two words to me that I didn’t understand but took to mean, “MOVE LEFT!” I was already ahead of him on that front. Finishing the drive, I mentioned the incident to a seasoned Aussie truck journalist who congratulated me. “I did it four times,” he responded. “It’s weird driving on the wrong side of the road.”

Hanover was an eye-opener on many fronts, from the sheer size of the exhibition to the rapidly advancing technological developments. I just hope someone will invite me back again because two days was simply not enough to see even half of what was on offer. Simply incredible!

Diesel/Hydrogen/Electric – the choice will soon be yours.

More Blog Posts You Will Love

More From In-depth

Got something to say? Say it here!

truckinwithkermie.com is for YOU and about YOU. We’d love to hear your stories. There are a number of ways to get in touch with us:

kermie@truckinwithkermie.com

(+61) 0418 139 415